When choosing an electrical panelboard for an industrial plant, serious consideration should also be given to quality and safety certifications, which attest to the adequacy of the product according to international standards. These certifications are a guarantee of reliability, durability and regulatory compliance, making it easier to choose among the options available on the market. In this article, we explore the main certifications for switchboards, explaining their importance for companies and for the safety of those working in critical environments.

IP rating: resistance to external contamination

The Ingress Protection (IP) rating is a key certification for assessing an electrical panel’s ability to resist external contamination, such as dust and liquids. Based on the EN 60529 standard, the IP rating is expressed with two digits:

- The first digit (0 to 6) indicates protection against solids and dust, with an increasing degree of safety.

- The second digit (0 to 9k) represents protection against liquids, from simple exposure to moisture to protection from powerful water jets even at high temperatures.

An electrical panel with a high IP rating is essential in manufacturing environments where the presence of dust or the risk of water contact can compromise the functionality of systems.

Degree of protection IK: mechanical impact resistance

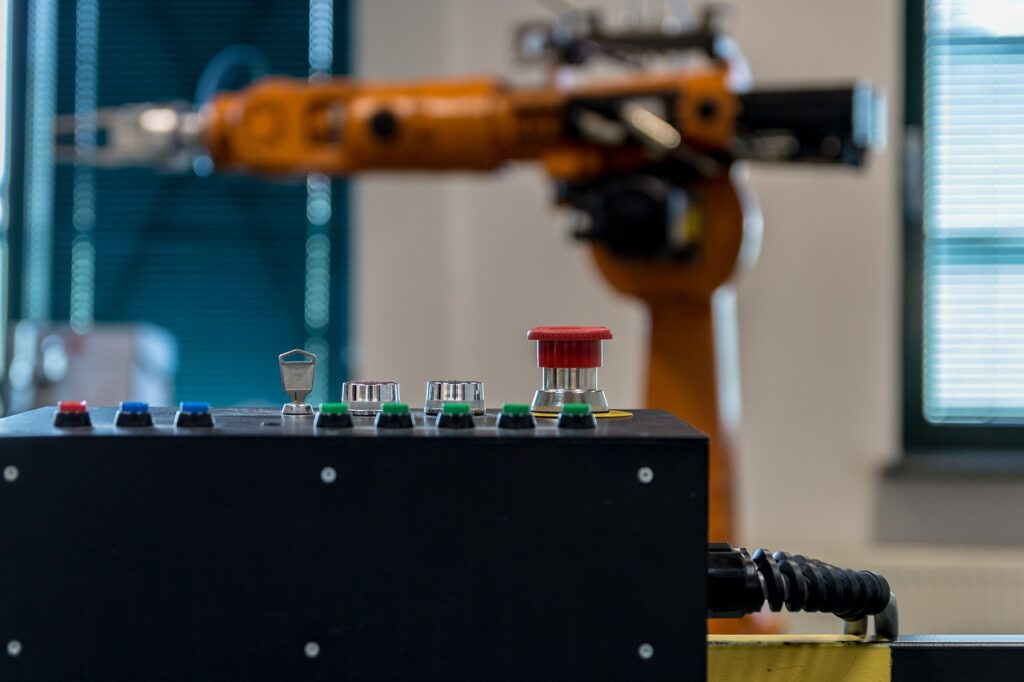

The degree of protection IK defines the resistance of the switchboard to external mechanical impacts, an important certification especially for equipment installed in complex industrial environments. The IK scale ranges from 0 to 10, where each value represents the switchboard’s ability to withstand impacts of varying intensity. IK is crucial in environments where machinery may be subject to accidental contact with heavy equipment or tools, reducing the risk of damage and subsequent downtime.

UL certification: International standards for the U.S. and Canadian markets

For those planning to export switchboards to North American markets, UL (Underwriters Laboratories) certification is essential. The C-UL-US Listing mark certifies that the product meets UL standards for the United States and CSA standards for Canada. In the U.S., the classification is set by NEMA (National Electrical Manufacturers Association), which defines the types of enclosures according to the environments in which they must operate. UL certification ensures safety and quality according to specific technical standards, improving the possibility of access to demanding international markets.

ATEX certification: safety for explosive environments

ATEX (ATmosphère EXplosible) certification is required for electrical panels intended for potentially explosive environments. This certification is essential for compliance with European legislation on safety in explosive atmospheres, defining risk zones and specific requirements based on the area of use. The presence of the ATEX mark makes it possible to identify products suitable for critical environments, such as refineries and chemical plants.

CE mark for European conformity

The CE mark is synonymous with compliance with the safety requirements and directives of the European Union. This certification attests that electrical panelss meet basic safety regulations and can be freely marketed within the European market.

Manufacturing companies must prepare a declaration of conformity that includes the directives and technical standards applied.

The international references for hygiene: EHEDG and 3-A SSI

In addition to electrical and mechanical safety, electrical panels used in industries such as food, chemical, and pharmaceutical must meet strict hygiene regulations. These sectors require high standards to avoid contamination and ensure a safe production environment:

- EHEDG: The European Hygienic Engineering and Design Group provides guidelines for hygiene in machinery design. It is a key standard for the food industry and helps comply with the Machinery Directive 2006/42/EC.

- 3-A SSI, Sanitary Standards, Inc,: a non-profit corporation of which four associations are members: American Dairy Products Institute, International Dairy Foods Association, Food Processing Suppliers Association, and International Association for Food Protection. It carries out an activity roughly equivalent to EHEDG but for the U.S. market. The current 3-A SSI maintains an extensive inventory of design criteria for processing equipment and systems developed using a modern consensus process based on ANSI requirements to promote acceptance by USDA, FDA and state regulatory authorities.

Certifications add value to quality and safety

Certifications are a regulatory requirement and a guarantee of quality and safety for those who want durable and reliable electrical panels. Investing in certified products enables companies to reduce operational risks, improve production quality and access international markets with high standards.

The electrical panels made by EiQ industrial have been subjected to proving laboratory tests certifying:

- IP66 degree of protection for maximum guarantee of sealing against dust and liquids;

- IP69 degree of protection to protect against access of liquids projected toward the enclosure at high pressure, from various angles, and at temperatures ranging from -5 to +80°C.

- Degree of protection IK10 , which guarantees the absolute robustness of the carpentry.

- UL US C certification(Nema 4x, 4, 1, 12) for theUS and Canadian markets for maximum assurance of dust and liquid tightness according to the standards found in the US and Canadian markets.

- ATEX category 3 zone 2/22 and category 2 zone 1/21 certification to ensure the safety of all environments with potentially explosive atmospheres

- EHEDG certification for critical components and accessories in the fabrication of dedicated electrical carpentry for application in Hygienic Design environments

- 3A certification establishes compliance with health and hygienic design standards accepted by the USDA, FDA and U.S. state regulatory authorities.